Researchers Develop Model to Accurately Predict Vessel Turnaround Time

Dynamic operation indicators improve vessel turnaround forecasting accuracy, boosting berth planning and overall port efficiency

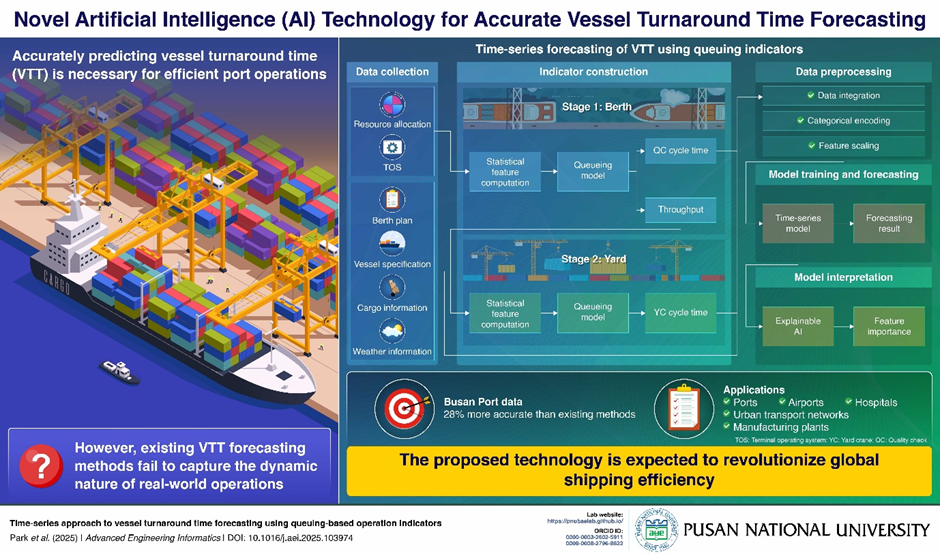

Growing port congestion demands smarter management. In a new study, researchers developed a dynamic forecasting x-framework using real-time operation indicators from a two-stage queuing model to predict vessel turnaround time. Tested with data from Busan Port, the model achieved up to 28% higher accuracy than traditional methods. By improving berth planning and resource allocation, this approach can significantly enhance efficiency and reduce delays in global port operations.

Image title: Dynamic Framework Enhances Accuracy of Vessel Turnaround Time Forecasting

Image caption: This study presents a time-series forecasting x-framework that integrates queuing-based operation indicators to improve vessel turnaround time prediction accuracy by up to 28%. Rather than directly optimizing waiting times, the research establishes a foundational predictive model that can support future efforts to enhance port efficiency and resource management.

Image credit: Professor Hyerim Bae from Pusan National University, Korea

License type: Original Content

Usage restrictions: Cannot be reused without permission

In the 21st century, as global trade expands and cargo volumes surge, ports face mounting pressure to operate efficiently. A key challenge lies in accurately predicting vessel turnaround time (VTT)—the period between a ship’s arrival and departure—which directly influences scheduling, congestion management, and energy use. Traditionally, forecasting methods have relied on static factors, such as vessel specifications or container volumes, which fail to capture the highly dynamic nature of port operations.

To address this gap, a team of researchers led by Professor Hyerim Bae and Master’s student Daesan Park from Department of Industrial Engineering at Pusan National University, South Korea, has devised an innovative time-series approach to VTT forecasting via queuing-based operation indicators (OIs). Their findings, published in Volume 69, Part B of the journal Advanced Engineering Informatics on 1 January 2026, were made available online on 15 October, 2025.

This new x-framework introduces operation indicators as quantitative measures of a system’s changing state, based on queueing theory. These indicators are derived from operational parameters such as arrival rates, service rates, and variability, calculated separately for berth and yard stages, and then linked to represent their interdependence. Unlike static models, this approach captures time-varying fluctuations in congestion, workload, and inter-stage interactions, offering a dynamic picture of how port systems evolve over time. Each variation in the OI corresponds to measurable changes in system behavior, effectively bridging theoretical modeling with real-world operations.

By feeding these dynamic indicators into time-series deep learning models, the x-framework learns how short-term variations in operational load affect overall turnaround performance. The result is a data-driven, explainable forecasting model that translates complex, fluctuating port activities into accurate and actionable predictions.

“Our x-framework can be directly applied to port operations to enhance berth scheduling, predict congestion, and optimize the allocation of cranes, trucks, and labor, leading to shorter vessel turnaround times and reduced energy consumption,” explains Prof. Bae. “Its strength lies in modeling how 'interconnected stages, such as vessel berthing, container handling, and yard transfer, affect one another through time. This perspective allows our x-framework to be extended naturally to other multi-stage service systems beyond ports.”

Potential applications range widely. In airports, similar indicators could help anticipate downstream delays in aircraft handling. In hospitals, they could model patient flow from registration to treatment, aiding workload balance. In urban transport, queue-based modelling could predict how congestion spreads through networks. In manufacturing, the x-framework could help prevent bottlenecks by mapping interdependencies between production lines and logistics systems.

As Mr. Park concludes, “By viewing each system as a chain of interdependent operations, our approach transforms complex processes into measurable, predictive indicators. It enables smarter, more reliable, and sustainable management systems that can improve everyday experiences—from faster travel and healthcare to more efficient production and mobility.”

Reference

Title of original paper: Time-series approach to vessel turnaround time forecasting using queuing-based operation indicators

Journal: Advanced Engineering Informatics

DOI: 10.1016/j.aei.2025.103974

Prof. Hyerim Bae

Professor Hyerim Bae is Dean of the Graduate School of Data Science and Professor of Industrial Engineering at Pusan National University, Republic of Korea. He directs the Human-Centered Carbon Neutral Global Supply Chain Research Center and serves as CEO of SmartChain Co., Ltd. His research focuses on AI-driven analytics, process mining, and sustainable logistics, particularly for smart ports and digital supply chains. He is an Associate Editor of IEEE Transactions on Big Data and the International Journal of Innovative Computing, Information, and Control. He contributes to national policy as a member of the Presidential Advisory Council on Science & Technology.

Lab: https://pnubaelab.github.io/

ORCID: 0000-0003-2602-5911

Daesan Park

Daesan Park is a Master’s student in Industrial Data Science and Engineering at Pusan National University, Republic of Korea. He received his B.S. degree in Industrial Engineering from Pusan National University. His research focuses on data-driven modeling of complex operational systems, with emphasis on queueing theory, process mining, and time series forecasting using deep learning. His interests include developing predictive x-frameworks for logistics and healthcare systems under uncertainty and dynamic conditions.

ORCID: 0009-0008-2796-8632

PURCS_181_Infographic_final.jpg

(1MB)

PURCS_181_Infographic_final.jpg

(1MB)