Discovering Faster, Smarter Heat Treatment for Lightweight Magnesium Metals

The present research utilizes a T-type specimen to uncover how electric pulses turbocharge grain growth in magnesium

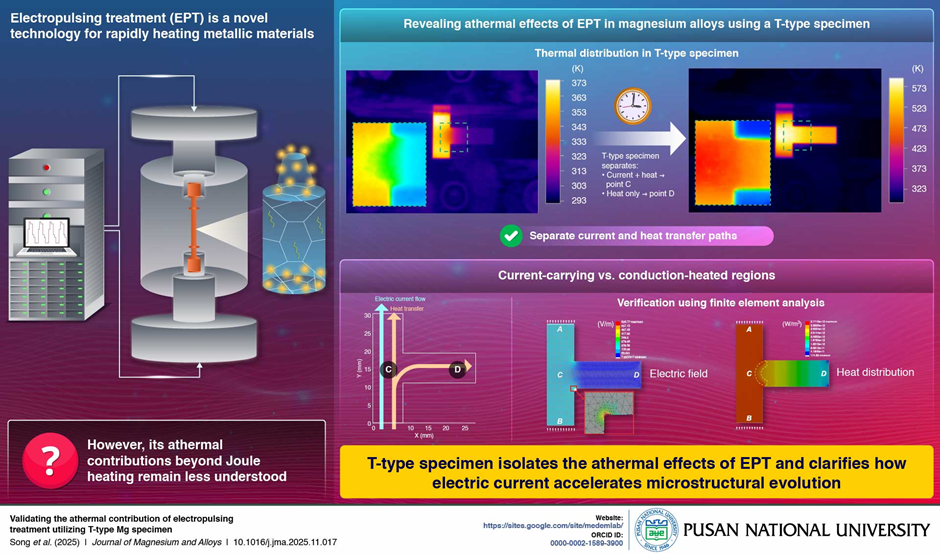

Electropulsing treatment rapidly heats metallic materials using high-density electrical pulses. Scientists at Pusan National University have now isolated its thermal and athermal effects in magnesium alloys using a novel T-type specimen. Their findings show that athermal effects significantly accelerate strain-induced boundary migration and grain growth—revealing how electropulsing can act as a fast, energy-efficient next-generation processing technology for lightweight metals.

Image title: Athermal Power of Electropulsing in Magnesium

Image caption: Researchers successfully distinguish the thermal and athermal contributions of electropulsing treatment in magnesium alloys using a T-type specimen.

Image credit: The authors

License type: Original Content

Usage restrictions: Cannot be reused without permission

Electropulsing treatment (EPT) is a state-of-the-art technology for rapidly heating metallic materials. The highly energy-efficient and eco-sufficient process utilizes a pulsed current or ‘electropulse,’ achieving unique effects such as electroplasticity and electropulsing anisotropy. It facilitates fast microstructural evolution in alloys—compared to the conventional furnace heat treatment (FHT) technique—possibly via athermal contributions that go beyond the effects of Joule heating.

Recent efforts by scientists to determine these athermal contributions have focused on direct comparisons between EPT and FHT at the same temperatures. However, such approaches are expected to suffer from significant experimental errors.

In a new study, a team of researchers from Korea, led by Professor Taekyung Lee, a faculty at the School of Mechanical Engineering at Pusan National University and the head of the Metal Design & Mechanics (MEDEM) Lab, has utilized a special “T-shaped” magnesium sample that facilitates the separation of the normal heating effects from the extra, athermal effects of EPT. Their findings were made available online and have been recently published in the Journal of Magnesium and Alloys on 08 December 2025.

Prof. Lee highlights the novelty of their work, “Our innovative T-type specimen methodology separates the current and heat transfer paths within a single specimen subjected to EPT. This pioneering methodology is contrasted by the conventional method that compared two different specimens: one with EPT and the other with FHT at a similar temperature. This traditional methodology possesses lots of inherent limitations. On the other hand, the T-type specimen methodology allows for the independent analysis of thermal and athermal effects of EPT within a single specimen.”

By carefully controlling the electric current in a pre-twinned AZ31 magnesium alloy sample, the team created two regions in the same sample that reached almost the same temperature, but only one region actually carried current. They found that the region carrying current showed enhanced strain-induced boundary migration mechanism, much faster grain growth, twin boundary removal, low-angle grain boundary reduction, dislocation annihilation, and softening than the region heated only by conduction. This proves that EPT can accelerate microstructural changes beyond what can be explained by heat alone.

The researchers verified their results using finite element analysis, which confirmed electric current flow confinement to a single beam and reliably reproduced the curved thermal distribution observed at the beam intersection in the T-type specimen.

Prof. Lee sheds light on the long-term implications of their innovative technology, “Measuring the athermal effect without Joule heat, or thermal effect, in the EPT process has long been a major challenge in academia. The developed methodology can help researchers understand the physical principles governing EPT. It is, therefore, expected to become a core standard measuring technology for advancing high-efficiency and eco-friendly forming techniques—known as electrically-assisted forming—for various metallic materials using electropulses.”

Overall, the T-type specimen approach presented in this study offers a robust x-framework for separating the thermal and athermal effects of EPT at the macroscale, thus providing an indispensable tool for elaborating their respective roles in EPT-driven microstructures and mechanical properties.

Reference

Title of original paper: Validating the athermal contribution of electropulsing treatment utilizing T-type Mg specimen

Journal: Journal of Magnesium and Alloys

DOI: 10.1016/j.jma.2025.11.017

About the author

Dr. Taekyung Lee is a Professor of Mechanical Engineering at Pusan National University and leads the Metal Design & Mechanics (MEDEM) Lab. His group studies advanced metal-forming technologies, including electropulsing treatment, additive manufacturing, and severe plastic deformation, with a focus on physics-based, machine-learning-assisted process optimization. He earned his Ph.D. from POSTECH in 2014, completed postdoctoral training at Northwestern University, and previously served as an assistant professor at Kumamoto University.

PURCS_186_Infographic_final.jpg

(1MB)

PURCS_186_Infographic_final.jpg

(1MB)